Hybrid

Manufacturing

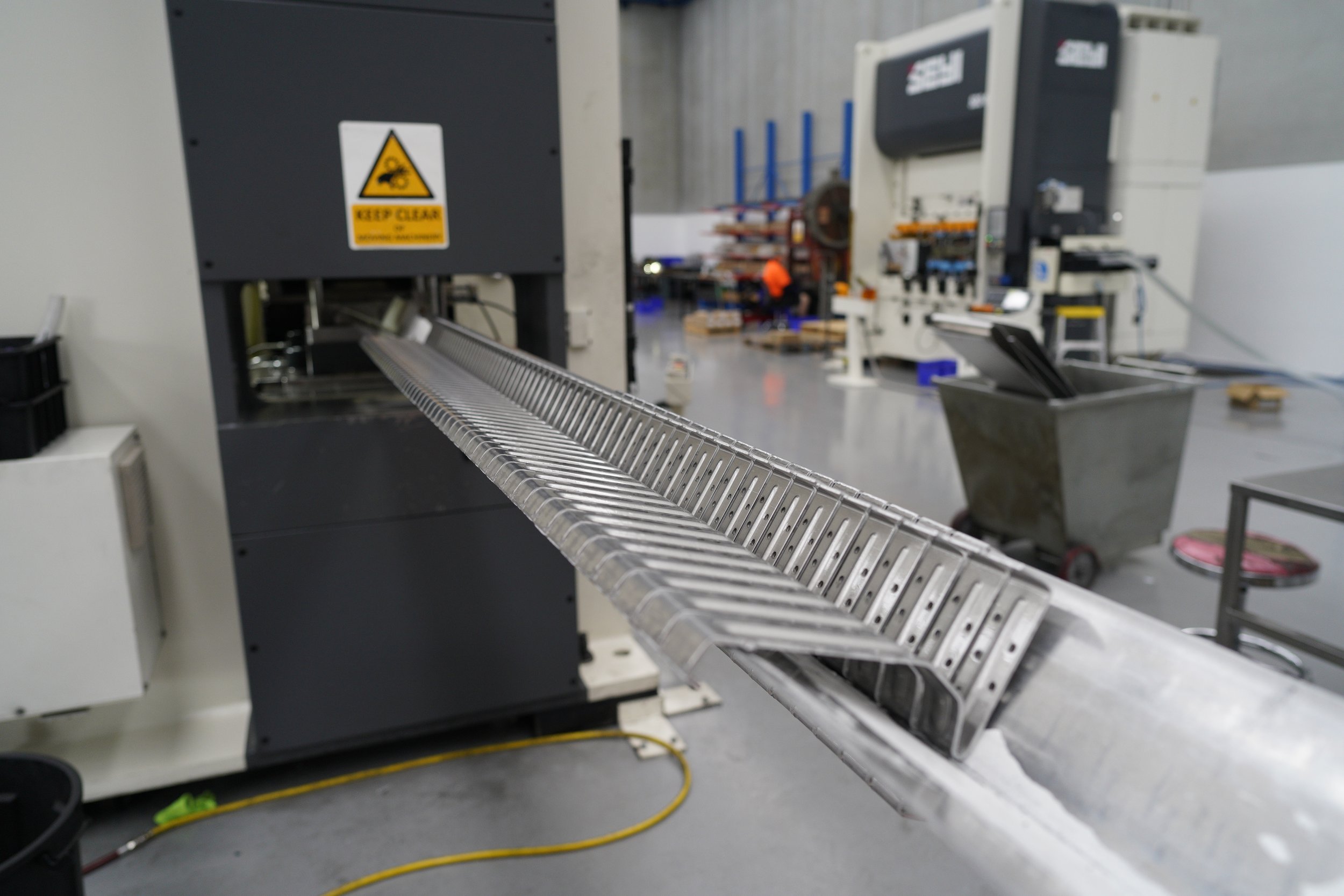

Hybrid manufacturing with Servo Press Technology

Hybrid manufacturing provides a revolutionary approach to production lines, that combines the best of additive and subtractive manufacturing methods. By integrating the versatility of Servo Press Technology, we deliver exceptional results that surpass traditional manufacturing processes. Here's how our hybrid manufacturing approach sets us apart:

The power of hybrid manufacturing

Hybrid manufacturing combines additive and subtractive manufacturing techniques to leverage their unique advantages. Additive manufacturing, such as 3D printing, enables us to build complex geometries and intricate designs layer by layer. Subtractive manufacturing, on the other hand, involves removing material to achieve precise shapes and finishes. By merging these methods, we can overcome design limitations and produce components with unprecedented flexibility and precision.

Versatility and flexibility

Our hybrid manufacturing approach offers unparalleled versatility, allowing us to adapt to a wide range of project requirements. Whether it's the production of intricate detailing or the manufacturing of complex components, we seamlessly integrate additive manufacturing with our Servo Press Technology. This flexibility empowers us to meet the unique needs of each client, delivering unique solutions that push the boundaries of traditional manufacturing approaches.

Precision and accuracy

Servo Press Technology plays a pivotal role in our hybrid manufacturing process, ensuring exceptional precision and accuracy. By combining the additive and subtractive methods, we achieve tight tolerances, fine details, and superior surface finishes. The advanced control systems of Servo Press Technology enable us to precisely control force and motion, resulting in consistent and reliable manufacturing outcomes.

Efficiency and speed

Hybrid manufacturing that uses Servo Press Technology offers significant advantages in terms of efficiency and speed. By optimising the integration of additive and subtractive processes, we streamline production cycles and reduce lead times. Additive manufacturing enables us to rapidly create complex structures, while subtractive manufacturing adds the finishing touches. This integrated approach ensures faster time-to-market while maintaining the highest quality standards.

Cost-effective solutions

Our hybrid manufacturing approach provides cost-effective solutions for our clients, by minimising material usage, reducing waste, and enhancing overall production efficiency. The ability to combine multiple manufacturing techniques in a single process eliminates the need for additional tooling, further reducing costs and shortening production timelines.

Continuous innovation

We continuously strive for innovation in hybrid manufacturing. Our team stays at the forefront of additive and subtractive technologies, exploring new materials, techniques, and processes. Through ongoing research and development, we ensure that our clients benefit from the latest advancements in hybrid manufacturing, enabling them to gain a competitive edge in their industries.

If you’d like to understand how hybrid manufacturing techniques can add efficiency and accuracy to your manufacturing process, reach out to the Form Manufacturing team today.